The recent progress in the column development brought to the market new type of highly efficient columns. These columns can be use either with standard HPLC instruments or with the instruments allowing separations at ultra high pressure (900 MPa). The conventional size of the column (150 x 4.6 mm) has been decreased significantly. The typical size of column for ultra high pressure liquid chromatography (UPLC) is 50 x 2.1 mm with sub 2 μm ID particles.

Reduction of the extra-column volume of instruments

The decrease in the column size increases the significance of the extra column volumes – the volume of the liners between the injector and column, as well as column and detector, injector itself and detection cell. The contribution of the extracolumn volumes can be almost neglected using the conventional size of the column (150 x 4.6 mm) and flow rate as high as 1 mL/min (ok, almost neglected;). On the other hand, if we are using the identical instrument with small columns (50 x 2.1 mm) the influence of the extracolumn contribution is much higher and can devastate our efficiency and separation.

In recent paper, F. Gritti et al. compared several currently commercially available HPLC instruments in terms of the influence of the extracolumn volumes on their separation power. They found, that the only optimization of the extracolumn volume in standard Agilent 1100 HPLC system from 15.2 μl to 3.8 μl, together with the change in the volume of detection cell (13 μl to 1.7 μl) dramatically improve the columns efficiency. The average increases in the average column efficiencies were 28, 41, and 278% for the 100 x 4.6 mm, the 50 x 4.6 mm, and the 50 x 2.1 mm I.D. Kinetex columns, respectively.

Using this very simple and almost costless modification of the current instruments, the full performance of large diameter column can be achieved. However, other approach has to be applied in case of the resolution power of small diameter columns.

Sample focusing with weak solvent

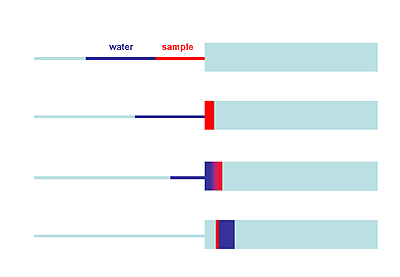

In the same article, authors showed the possibility of column efficiency improvement with the injection of the weak solvent plug after the sample. After the sample injection, the weak solvent (water in reversed-phase chromatography) is injected and if there is no retention of this weak solvent on the stationary phase, the width of the sample band adsorbed at the column inlet can be reduced by diluting the sample with the weak solvent. Following picture (adapted from the discussed article) describes the whole idea.

With this approach, the sample dispersion on the column inlet is almost eliminated and it is possible to achieve apparent column efficiency close to the maximum possible for most columns currently available, including the short 2.1 mm I.D. columns packed with 2.6 μm superficially porous particles.

These examples show that it is possible to improve the HPLC instrument performance using very simple and costless approaches. However, the further improvement in the instrumentation (especially decrease in the instrumental extracolumn volumes) is necessary to be able to reach the full possible performance of the new, highly efficient, columns.